Recently, the Ministry of Industry and Information Technology officially announced the 2025 Excellence-level Smart Factory list, with Sunstone Development Co., Ltd.’s project “High-precision Aluminum Anode Process Dynamic Optimization Smart Factory” successfully selected.

This national recognition reflects the long-term collaboration and joint innovation between Yonyou Intelligent Manufacturing and Sunstone Development. As the project’s core technology partner, Yonyou leveraged its industry-leading digital-intelligence solutions and full-stack smart manufacturing capabilities to help Sunstone build a modern factory featuring end-to-end connectivity and comprehensive intelligent operations.

The “Smart Factory Gradient Cultivation Initiative” is jointly promoted by six national authorities, the Ministry of Industry and Information Technology, the National Development and Reform Commission, the Ministry of Finance, the State-owned Assets Supervision and Administration Commission of the State Council, the State Administration for Market Regulation, and the National Data Administration. Its goal is to identify and recognize manufacturing enterprises that excel in digital transformation, networked collaboration, and intelligent upgrading.

Sunstone Development’s selection as an Excellence-level Smart Factory not only signifies that its intelligent manufacturing maturity has reached Level 3 of the national Intelligent Manufacturing Capability Maturity Model, but also reflects the proven applicability and industry-leading value of the Yonyou BIP Intelligent Manufacturing System in complex manufacturing scenarios.

As a global leader in prebaked anode production, Sunstone Development has ranked first in China’s exports for 17 consecutive years. Facing the dual challenges of national “dual carbon” goals and international market competition, the company has proactively formulated a “1+N” digital intelligence strategy, aiming to build a modern manufacturing system driven by a smart headquarters and coordinated by multiple low-carbon intelligent factories.

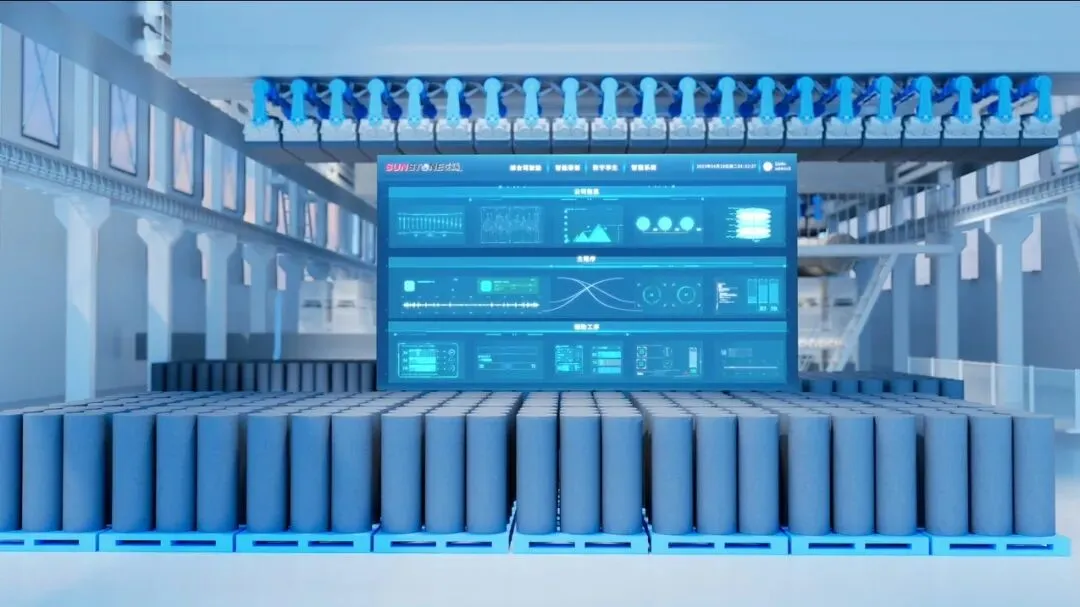

In the construction of the smart factory, Yonyou supported Sunstone Development in achieving a comprehensive intelligent upgrade from bottom-level automation to top-level decision-making. By deploying the Yonyou BIP Intelligent Manufacturing Platform, the project realized vertical integration across five levels, equipment, control, factory, enterprise, and collaboration, as well as horizontal coverage across R&D, production, operations, and supply chain. At its core, the platform leverages digital twin technology and deep IT/OT integration, enabling transparent factory management and system-level optimization, fundamentally transforming the traditional production model that relied on human experience.

In terms of scenario enablement, Yonyou helped Sunstone build 19 intelligent manufacturing scenarios across 8 key business areas, with 8 scenarios deeply applying AI algorithms. This resulted in an AI adoption rate of 42%, far exceeding the industry average of 20%, showcasing Yonyou’s strong expertise in industrial intelligence.

- Intelligent R&D & Process Optimization: The Yonyou PLM system enables product modeling, virtual validation, and process knowledge base accumulation, significantly shortening R&D cycles and reducing redundant design.

- Flexible Production & Precision Scheduling: The Yonyou APS system optimizes multi-factory collaboration, order allocation, and mixing-scheduling algorithms, ensuring efficient resource allocation and lean production.

- Quality Control: Real-time monitoring and AI-powered analysis enhance process control accuracy and product quality consistency.

- Supply Chain & Logistics: The Yonyou intelligent procurement and logistics collaboration platform connects over 300 suppliers, building a highly efficient and collaborative supply chain ecosystem.

Data-driven intelligence lies at the core of Yonyou’s smart manufacturing solutions. By deploying the Yonyou Industrial Internet Platform, Sunstone’s factories achieved second-level data collection and real-time circulation of full production data, completely breaking information silos. This shift transformed enterprise management from “experience-driven” to “data-driven,” providing strong support for process optimization, energy management, and anomaly detection.

Ye Xiulin, General Manager of Yonyou’s Manufacturing Industry and Intelligent Manufacturing Division, stated:

“The Sunstone Smart Factory project represents the in-depth practice of Yonyou BIP in the carbon industry. We not only focus on individual technology applications but also emphasize overall system collaboration and end-to-end business optimization. This project successfully integrates AI, IoT, big data, and digital twin technologies with manufacturing, creating a replicable and scalable path for intelligent transformation.”

The recognition as an Excellence-level Smart Factory marks a key milestone in Sunstone’s journey of intelligent transformation, and further affirms Yonyou’s technological and service capabilities in smart manufacturing. Yonyou will continue to deepen its strategic cooperation with Sunstone, integrating intelligence with production management to help further optimize energy consumption and emissions, enhance green competitiveness, and solidify Sunstone’s leadership in the global prebaked anode market.

Looking ahead, Yonyou will also assist Sunstone in exporting its smart factory models, standards, and solutions to empower collaboration across the entire value chain, driving high-quality upgrades in the prebaked anode industry and injecting new momentum into the intelligent transformation of China’s manufacturing sector.