TOKYO BOEKI MATERIALS LTD, Jonan Steel Co., Ltd., and Yonyou Network Technology Co., Ltd. have officially entered into a strategic partnership to implement an AI-powered scrap classification system. This groundbreaking project leverages Yonyou’s advanced BIP AI technology to transform the steelmaking process at Jonan Steel — one of Japan’s leading electric furnace steel manufacturers.

Driving Smart Transformation in Japan's Steel Industry

The AI scrap grading system by Yonyou is designed to replace traditional manual inspection with automated, intelligent grading. Using high-resolution vision systems and AIoT algorithms, the system can analyze and classify scrap steel with precision down to 0.6 mm.

This project has been featured by Japan Metal Daily, highlighting its innovation and significant contribution to Japan’s digital manufacturing landscape.

Proven AI Capability with Industry-Wide Adoption

Yonyou’s AI scrap grading system has already been successfully deployed in 80+ steel enterprises, with over 1.4 million scrap images processed and 565,000+ trucks graded. As a proven solution in Asia’s steel sector, it brings measurable improvements in:

Scrap classification accuracy

Operational efficiency and automation

Procurement and supply chain optimization

Labor cost reduction and environmental sustainability

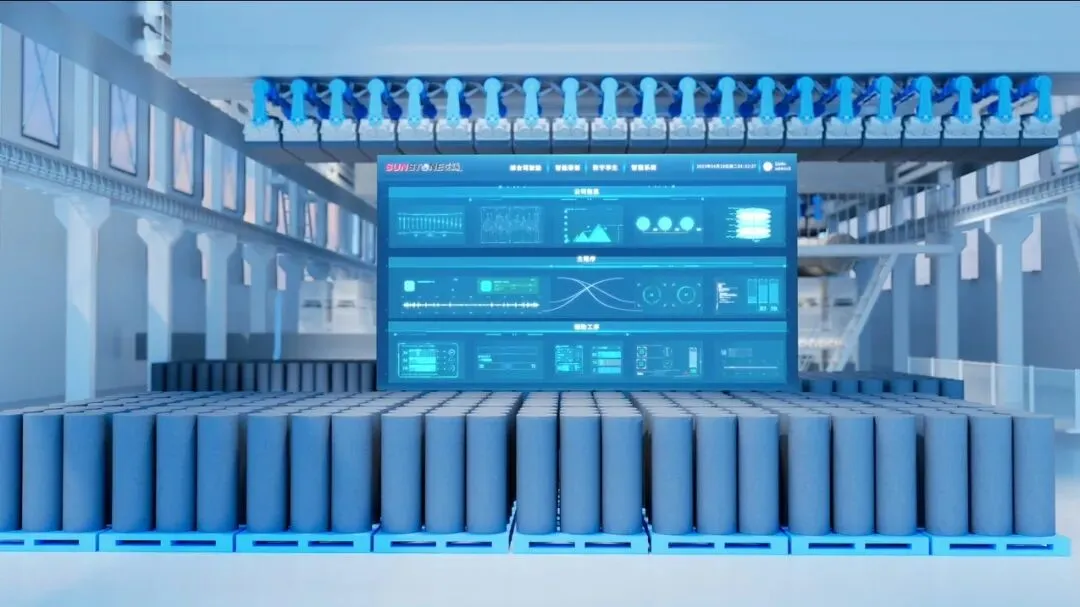

Building a Full-Stack AI Ecosystem for Manufacturing

This collaboration marks a deeper commitment between Yonyou and Japan’s steel industry. It is not just about grading scrap — it’s about integrating AI across the entire electric furnace production chain, enabling smarter purchasing, precision manufacturing, and predictive maintenance.

With over 22 years of global expansion, Yonyou continues to lead in enterprise digital transformation by delivering integrated AI, ERP, and industry-specific solutions that drive competitiveness and long-term growth.